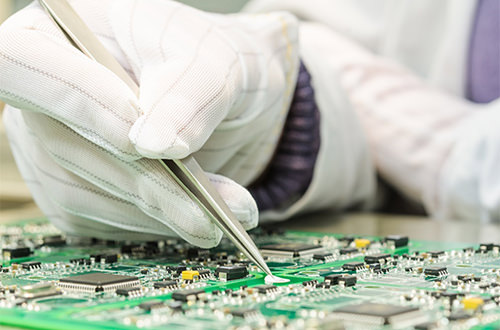

The standard of excellence and reliability is in our genes. Every step of manufacturing is monitored and tracked for quality assurance. The process of quality control starts at the component level all the way to the shipping department, ensuring our customers receive quality, robust, and trouble-free laser processing machines all the time.

VTron lasers are superbly handcrafted in the United States of America utilizing the best components available. Providing uncommon quality, reliability and service is and will always be the core foundation of our company’s principle.

By adhering vigorously to our 10 principles of quality control:

- The simplicity of design (Modular design)

- Organized and neat engineering (Ease of troubleshooting)

- Triple quality checks (Three quality check charts are kept and compared)

- The responsible production team (Every component is initialed and dated by the production personnel)

- Communication and cooperation (All departments communicate daily to keep up with production)

- Flexible manufacturing (Components can be switched among our line of machines for quick turnaround)

- Observing delivery time (Fully stocked parts department allowing for a quick part and service support)

- Clear and focused objectives (We plan to stay in business for a very long time therefore we build our lasers to last)

- Continuous improvements (Our R&D labs are always working to stay ahead by developing superior and intelligent products)

- Quality components (Superior components translate to superior products)

This continuous process of quality control reflects our commitment to keeping our customers satisfied and their expectations fulfilled. That is our pledge to our customers.