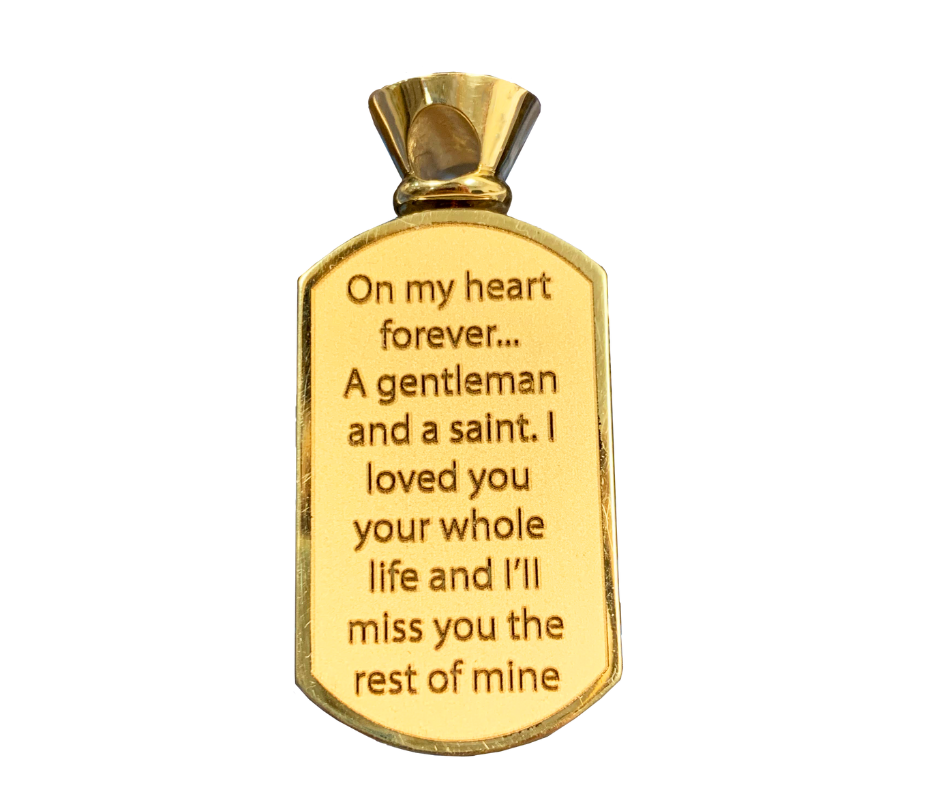

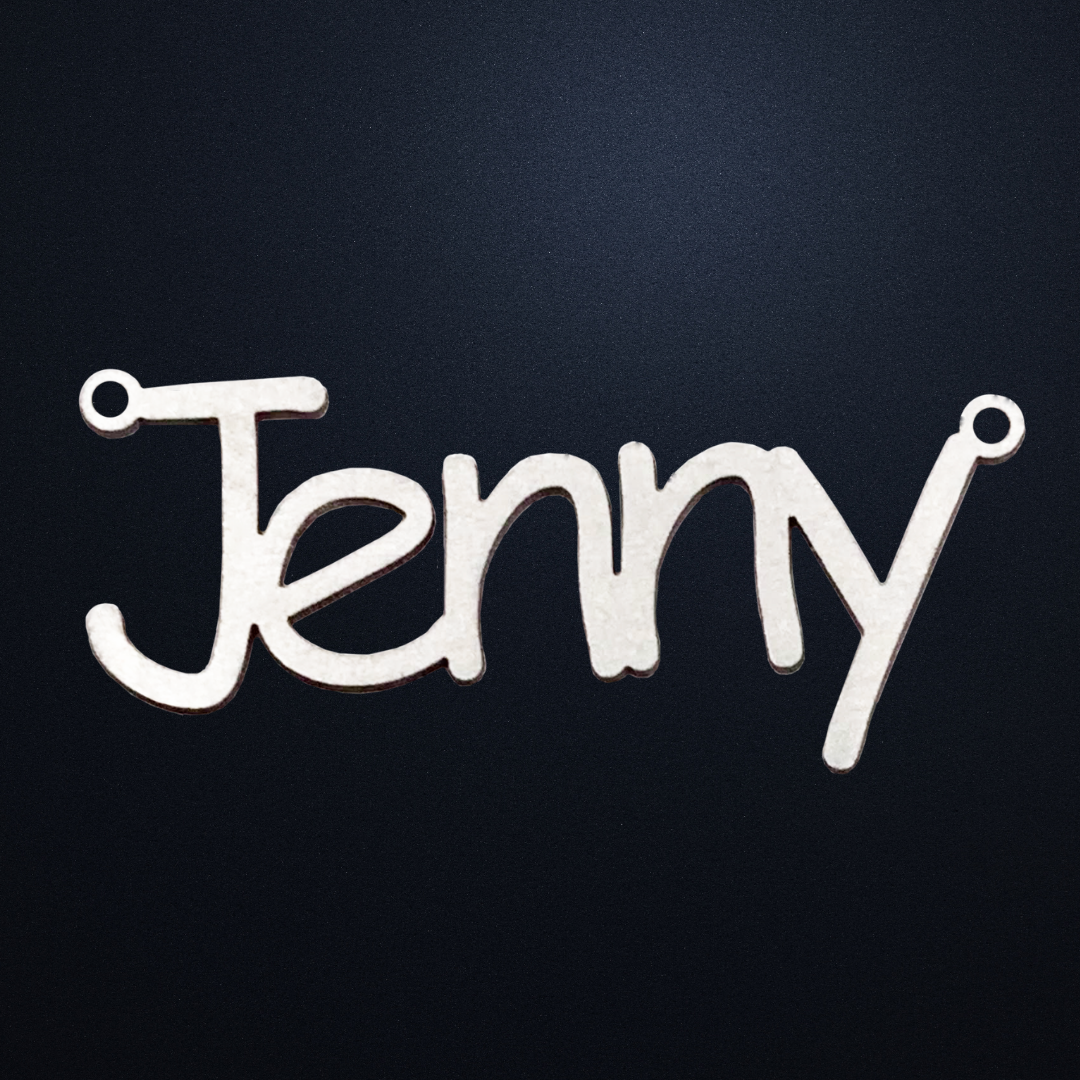

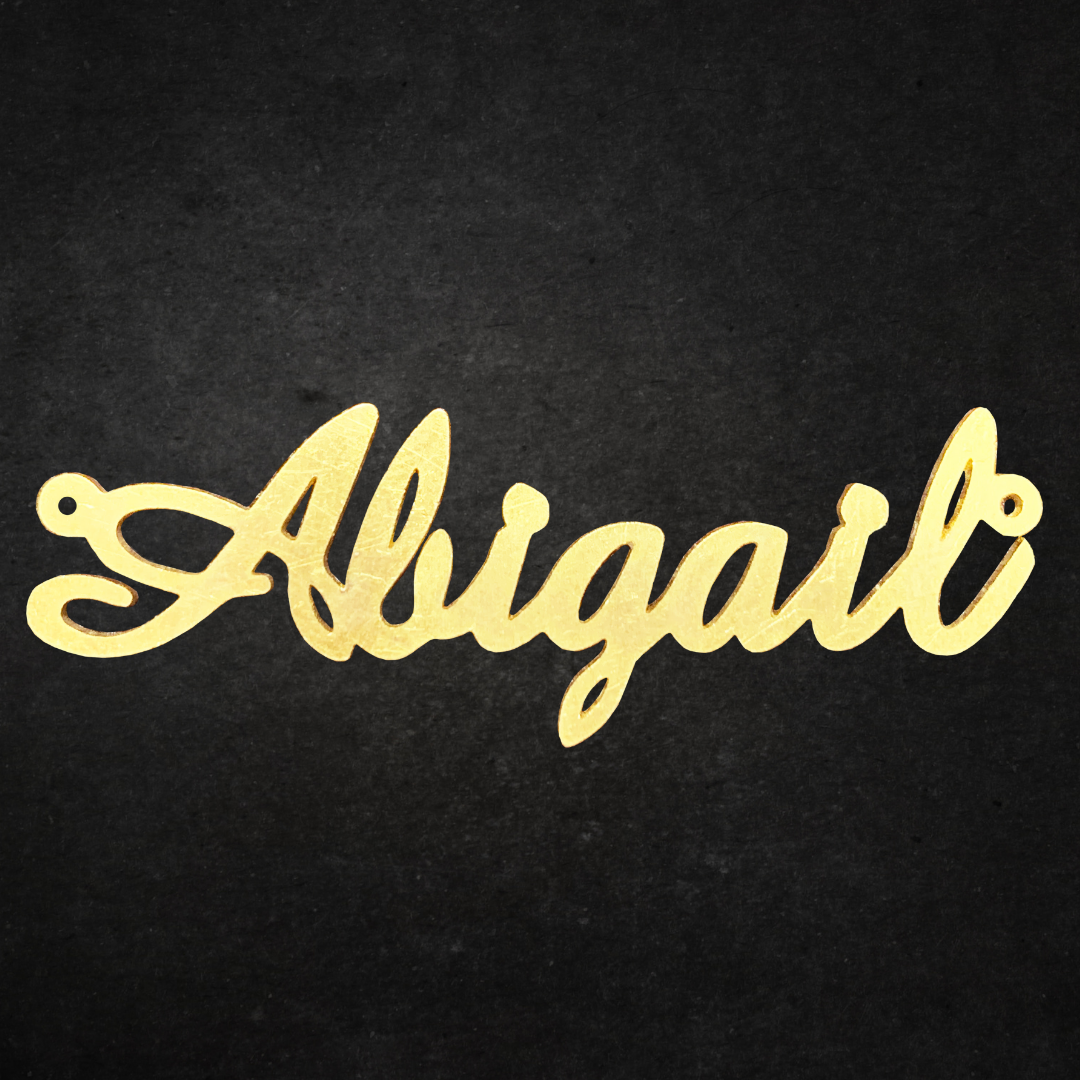

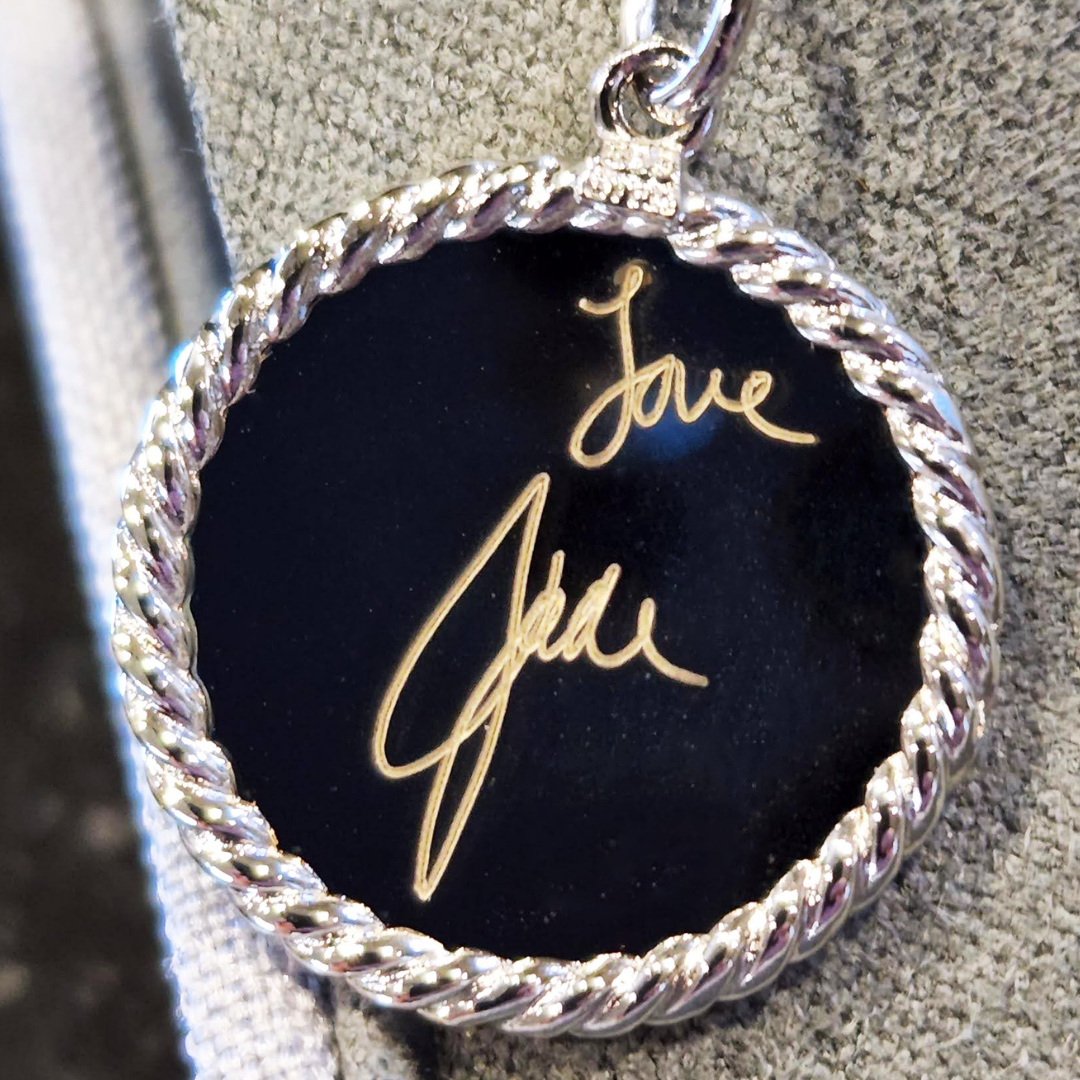

Laser marking and engraving of ferrous metals including precious metal alloys for the jewelry and Fashion industries offers a permanent and versatile way to customize rings, bangles, bracelets, nameplate necklaces, coins, dyes, badges, wedding bands, pendants, and religious jewelry icons. VTron Lasers marking, engraving and cutting machines are a high-speed, low-impact solution used for a wide range of material processing and by a variety of industries

Today’s laser technology has become the most popular choice for jewelry branding, deep engraving, and adornments, due to their high-efficiency low maintenance cost, ease of operation and extreme reliability, and the lack of consumable requirements. In addition, laser engraving, marking, and cutting systems takes up a small footprint and can be easily integrated into production lines or configurable automation process.

VTron Lasers can engrave, anneal, color, mark, and cut on a variety of substrates in 2D, 2.5D as well as 3D, and on different types of surfaces including, flat, cylindrical, curved, or complex surfaces. Based on the customers’ application VTron manufactures a variety of systems for engraving, marking, welding, and cutting to meet the customer’s requirements.

VTron Lasers’ systems come with standard two days of training, 2 years of technical support, and are backed up by a robust warranty and factory support.