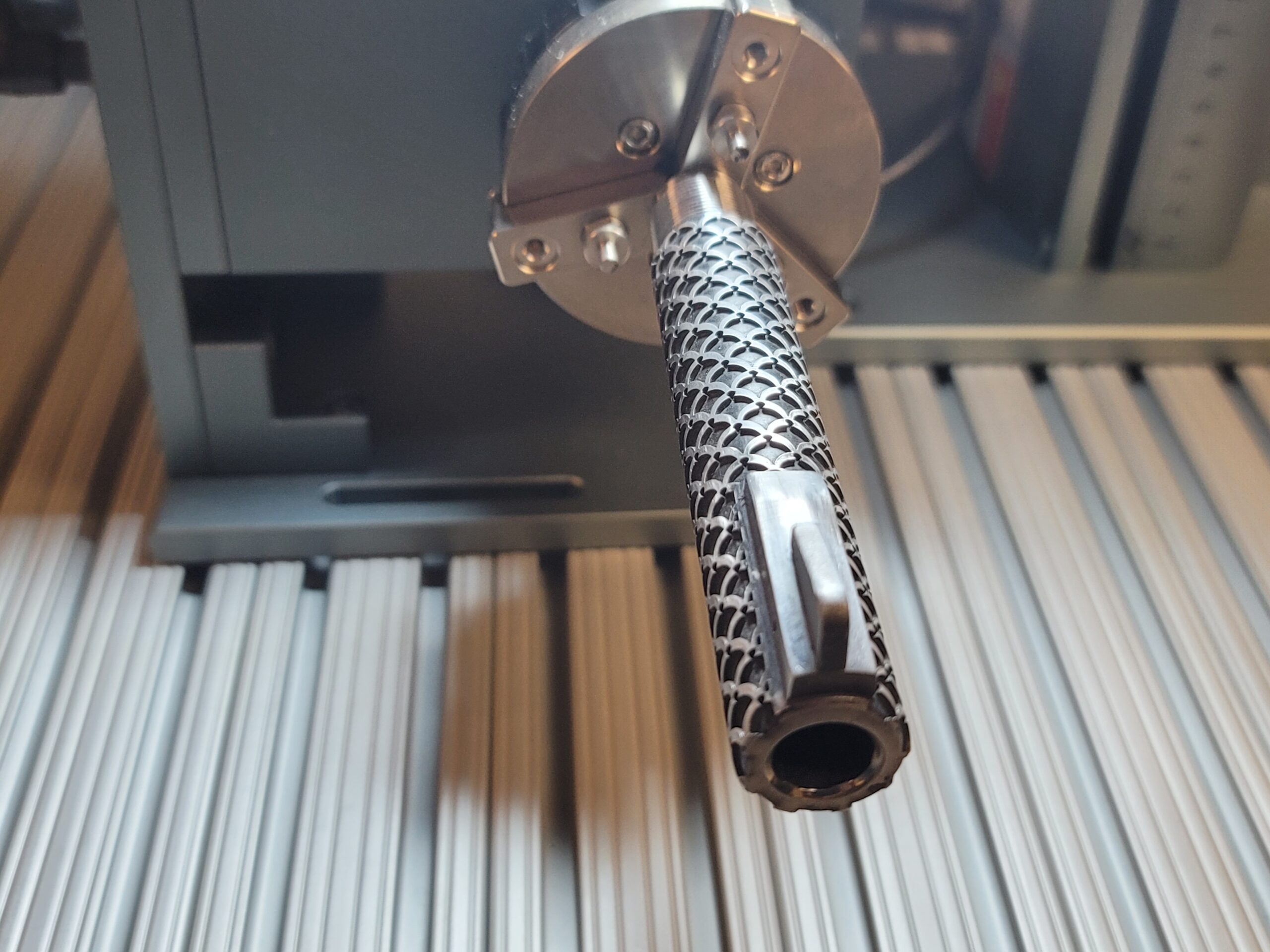

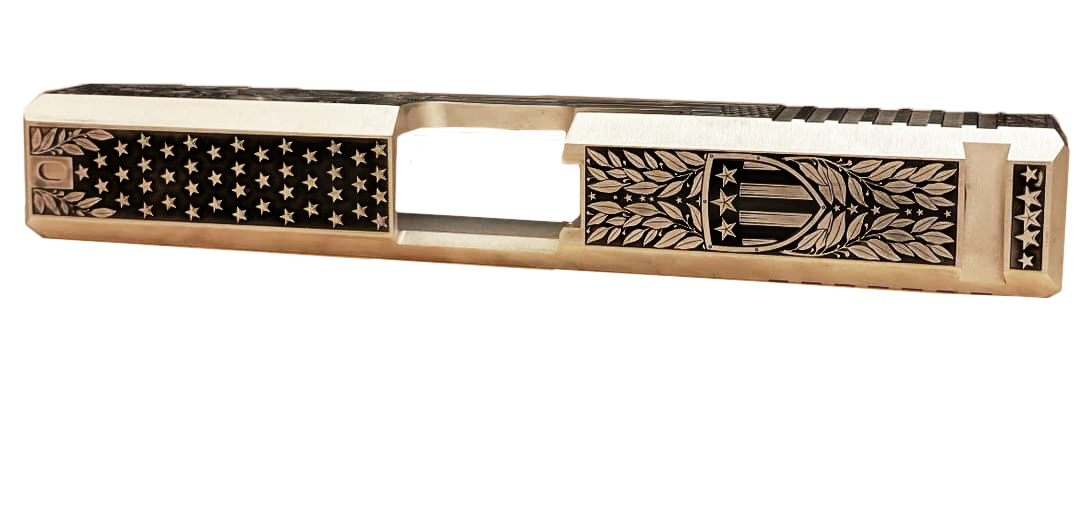

Two avenues are employed in modern-day firearms manufacturing, the first targeting the manufacturing aspect which targets micro-cutting of components, deep engraving, and drilling for gas release, NFA regulatory micro engraving for serial numbers, micro engraving on ammunition for tracing purposes, and the other avenue is an artistic presentation and functionality application such as Polymer stippling or texturing of slides and upper receivers that offer a slip control function.

VTron Lasers offers an amazing level of multi-dimensional and complex surface processing in 2D, 2.5D, and true 3D relief engraving and surface texturing on a wide range of organic and non-organic materials such as Chrome Molly, 300 & 400 series Stainless steel, Brass, Copper, Aluminum, Cobalt, Bronze, CP20, Titanium, Platinum, Gold, Silver, Wood, Ceramic polymer coatings such as Cerakote and Duracoat, metal coloring or annealing

VTron Laser Engraving Systems deliver direct parts engraving for the purpose of Artistic Adornment, Branding, and Product Traceability and Identification. Built-in the USA to the highest standards utilizing the finest optics, electronics, hardware, and software that are seamlessly integrated assuring a long robust performance

Features:

- Purpose-built laser engraving platforms for specific application or requirements

- Automated process of serialization and software interface

- Engraving on flat, cylindrical, and curved, and complex surfaces

- Twenty-nine Barcode as well as 2D or 3D Data Matrix subsurface engraving for NFA or ATF compliance

- Multi-axis motion automation with CNC control for up to 9 axis stages.